A514 Carbon Steel Coil

Classification :

PRODUCT DETAILS

Keywords: Shengqiang Steel

A514 Carbon Steel Coil Description

ASTM A514 steel is available in several grades: A, B, C, E, F, H, J, K, M, P, Q, S, and T, all of which have the same mechanical properties. ASTM A514 steel plates are conventionally quenched and tempered steel. ASTM A514 steel coil is known for its high yield strength, weldability and toughness, even at low temperatures. ASTM A514 steel is a special high-strength steel, mainly used as building structural steel.

Product Parameters

Product Name | A514 Carbon Steel Coil |

Production Process | Hot Rolling, Cold Rolling |

Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

Width | 45mm-2200mm |

Length | Custom Size |

Thickness | Hot Rolling: 2.75mm-100mm |

Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

A514 | C | Mn | P | S | Ni | Cr | Mo |

GradeA | 0.15-0.21 | 0.80-1.10 | 0.035 | 0.4-0.8 | - | 0.5-0.8 | 0.18-0.28 |

GradeB | 0.12-0.21 | 0.70-1.0 | 0.035 | 0.20-0.35 | - | 0.4-0.65 | 0.15-0.25 |

GradeC | 0.1-0.2 | 1.10-1.5 | 0.035 | 0.15-0.30 | - | - | 0.15-0.30 |

GradeE | 0.12-0.20 | 0.4-0.7 | 0.035 | 0.2-0.4 | - | 1.40-2.0 | 0.4-0.6 |

GradeF | 0.1-0.2 | 0.60-1.0 | 0.035 | 0.15-0.35 | 0.70-1.0 | 0.4-0.65 | 0.4-0.6 |

GradeH | 0.12-0.21 | 0.95-1.3 | 0.035 | 0.20-0.35 | 0.3-0.7 | 0.4-0.65 | 0.2-0.3 |

GradeJ | 0.12-0.21 | 0.45-0.7 | 0.035 | 0.20-0.35 | - | - | 0.50-0.65 |

Mechanical Properties

A514

| Thicknessmm | Yield Strength Min Mpa | Tensile Strength Mpa | Elongation Rate Min% |

20 | 690 | 760-895 | 18 | |

20-65 | 690 | 760-895 | 18 | |

65-150 | 620 | 690-895 | 18 |

Physical Performance

Physical Performance | Metric | Imperial |

Density | 7.85 g/cm3 | 0.284 lb/in³ |

Scope of Application

ASTM A514 steel plate is used where welding, processing, and ultra-high-strength steel are required to reduce weight or meet high-strength requirements. ASTM A514 steel plate is a commonly used structural steel in building construction, used in cranes or other large machinery that bears high loads.

| China | USA | Germany | Japan | France | U.K. | internationality |

|

GB3077 |

AlSI |

DIN |

JIS |

NE |

BS |

ISO |

|

20Mn2 |

1320 1221 |

20Mn5 |

SMn21 |

20M5 |

150M19 |

- |

|

30Mn2 |

1330 |

30Mn5 |

SMn24 |

32M5 |

150M28 |

- |

|

35Mn2 |

1335 |

36Mn5 |

SMnl |

35M5 |

150M36 |

- |

|

40Mn2 |

1340 1341 |

- |

SMn2 |

40M5 |

- |

- |

|

45Mn2 |

1345 |

46Mn7 |

SMn3 |

45M5 |

- |

- |

|

50Mn2 |

1052 |

50Mn7 |

- |

55M5 |

- |

- |

|

20MnV |

- |

20MnV6 |

- |

|

- |

- |

|

30Mn2MoW |

- |

-- |

- |

|

- |

- |

|

27SiMn |

- |

27MnSi5 |

- |

|

- |

- |

|

35SiMn |

- |

37MnSi5 |

- |

38MS5 |

- |

- |

|

42SiMn |

- |

38MnSi4 46MnSi4 |

- |

38MS5 |

- |

- |

|

20SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

25SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

37SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

40B |

14B35 |

35B2 |

- |

- |

- |

- |

|

45B |

50B46H |

45B2 |

- |

- |

- |

- |

|

50B |

14B50 |

- |

- |

- |

- |

- |

|

4OM∏B |

15B41 |

- |

- |

- |

- |

- |

|

45MnB |

15B48 50B44 |

- |

- |

- |

- |

- |

|

20Mn2B |

- |

- |

- |

- |

- |

- |

|

20MnMoB |

80B20 |

- |

- |

- |

- |

- |

|

15MnVB |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

|

20MnVB |

- |

- |

- |

- |

- |

- |

|

40MnVB |

- |

- |

- |

- |

- |

- |

|

20MnTiB |

- |

- |

- |

- |

- |

- |

|

25MnTiBRE |

- |

- |

- |

- |

- |

- |

|

2OSiMnVB |

- |

- |

- |

- |

- |

- |

|

15Cr |

5015 5115 |

15Cr3 |

SCr21 |

12C3 |

523A14 523M15 |

- |

|

15CrA |

- |

- |

- |

- |

- |

- |

|

20Cr |

5120 |

20Cr4 |

SCr22 |

18C3 18C4 |

527A19 527M20 |

683/11 20Cr4 20CrS4 |

|

30Cr |

5130 |

28Cr4 |

SCr2 |

28C4 32C4 |

530A30 530A32 |

- |

|

35Cr |

5135 |

34Cr4 37Cr4 |

SCr3 |

38C4 |

530A36 |

683/8 3、 3a、 3b |

|

40Cr |

5140 |

38Cr4 41Cr4 |

SCr4 |

42C4 |

530A40 530M40 |

683/1 4、 4a^ 4b |

|

45Cr |

5145 |

42Cr4 |

SCR5 |

45C4 |

- |

- |

|

50Cr |

5150 5152 |

- |

- |

50C4 |

En48 |

- |

|

38CrSi |

- |

- |

- |

- |

- |

- |

|

12CrMo |

4119 |

13CrMo44 |

- |

12CD4 15CD2 |

- |

- |

|

15CrMo |

ASTM A-387Gr. B |

15CrMo5 16CrMo44 |

SCM21 |

15CD4. 05 |

BS1653 |

- |

|

20CrMo |

4118 |

20CrMo5 22CrMo4 |

SCM22 |

18CD4 20CD4 |

CDS 12 CDSllO |

- |

|

30CrMo |

4130 |

25CrMo4 |

SCM2 |

30CD4 |

CDS 13 |

- |

|

30CrMoA |

- |

32CrMol2 3ICRMo12 |

- |

- |

- |

- |

|

35CrMo |

4135 4137 |

34CrMo4 35CrMo4 |

SCM3 |

35CD4 |

78A37 |

683/1 C35ea C35eb |

|

42CrMo |

4140 4142 |

41CrMo4 42CrMo4 |

SCM4 |

40CD4 42CD4 |

708M40 708A42 709M40 |

683/1 3 |

|

12CrMoV |

- |

- |

- |

- |

- |

- |

|

35CrMoV |

- |

35CrMoV5 |

- |

- |

- |

- |

|

12CrlMoV |

- |

13CrMoV4.2 |

- |

- |

- |

- |

|

25Cr2MoVA |

- |

24CrMoV5.5 |

- |

- |

- |

- |

|

25Cr2MolVA |

- |

- |

- |

- |

- |

- |

|

20CR3MoWVA |

- |

21CrVMoW12 |

- |

- |

- |

- |

|

38CrMoΛl |

6370 (ΛMS) |

34CrAlMo5 41CrAlMo7 |

SACM645 |

40CAD6.12 |

905M39 |

683/10 41CrAlMo74 |

|

20CrV |

6120 |

22CrV4 |

- |

22CrV4 |

- |

- |

|

40CrV |

6140 |

42CrV |

- |

42CrV4 |

- |

- |

|

50CrVA |

6150 |

50CrV4 |

SUPlO |

50CV4 |

735A50 |

- |

|

15CrMn |

- |

16MnCr5 |

- |

16MC5 |

- |

- |

|

20CrMn |

5120 |

20MnCr5 |

SMC21 |

20MC5 |

- |

- |

|

40CrMn |

5140 |

- |

SMC3 |

- |

- |

- |

|

20CrMnSi |

- |

- |

|

- |

- |

- |

|

25CrMnSi |

- |

- |

SMKl |

- |

- |

- |

|

30CrMnSi |

- |

- |

- |

- |

- |

- |

|

30CrMnSiA |

- |

- |

- |

- |

- |

- |

|

35CrMnSiA |

- |

- |

SMK2 |

- |

- |

- |

|

20CrMnMo |

4119 |

20CrMo5 |

SCM23 |

- |

- |

- |

|

40CrMnMo |

4140 |

- |

- |

- |

- |

- |

|

20CrMnTi |

- |

- |

SMK22 |

- |

- |

- |

|

30CrMnTi |

- |

30MnCrTi4 |

- |

- |

- |

- |

|

20CrNi |

3120 |

20NiCr6 |

- |

20NC6 |

637A16 637M17 |

- |

|

40CrNi |

3140 |

46NiCr6 |

SNCl |

35NC6 |

640A35 640M40 |

- |

|

45CrNi |

3145 |

45NiCr6 |

- |

- |

- |

- |

|

50CrNi |

3150 |

- |

- |

- |

- |

- |

|

12CrNi2 |

3115 |

14NiCrlO |

SNC21 |

IONCll 14NC11 |

- |

- |

|

12CrNi3 |

3310 |

13NiCrl2 |

SNC22 |

10NC12 14NC12 |

655A12 655M13 |

- |

|

20CrNi3 |

- |

22NiCrl4 |

- |

20NC11 |

- |

- |

|

30CrNi3 |

- |

28NiCrlO 31NiCrl4 |

SNC2 |

30NC11 30NC12 |

- |

- |

|

37CrNi3 |

- |

35NiCrl8 |

SNC3 |

35NC15 |

- |

- |

|

12Cr2Ni4 |

E3310 |

14NiCrl8 |

- |

12NC15 |

- |

- |

|

20Cr2Ni4 |

E3316 |

22NiCrl4 |

- |

20NC14 |

659A15 659M15 |

- |

|

20CrNiMo |

8620 8720 |

20NiCrMo2 21NiCrMo2 |

- |

20NCD2 |

805A20 805M20 |

- |

|

40CrNiMoA |

4340 9840 |

36NiCrMo4 40NiCrMo6 |

SNCM8 |

35NCD5 40NCD3 |

817M40 816M40 |

- |

|

45CrNiMoVA |

4437 |

- |

SNCM9 |

- |

- |

- |

|

18Cr2Ni4WA |

|

|

|

|

|

|

|

25Cr2Ni4WA |

|

|

|

|

|

|

Packing and delivery

Steel packaging board combines most of the plastic properties, impact resistance, low temperature resistance, wear resistance, chemical corrosion resistance, self-lubrication, and impact energy absorption. It can protect steel from impact, water resistance, and pressure resistance during storage and transportation without damage.

CUSTOMER FEEDBACK

Our products and services have received widespread praise from domestic and foreign customers. We sincerely welcome friends from all over the world to visit our company for inspection and long-term cooperation .

FACTORY WORKSHOP

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

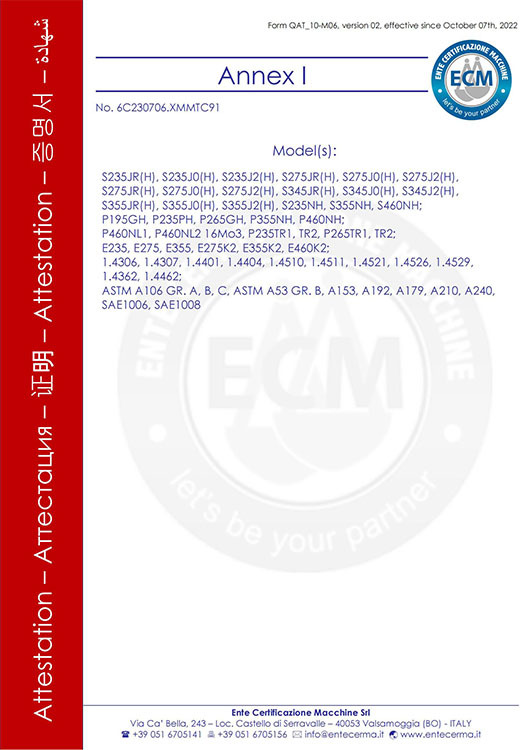

CERTIFICATE

Honor

Honor

Honor

Honor

Honor

Honor

APPLICATION FIELD

Airplane

Bridge

Mining

Wind power generation

FAQ

How can we guarantee quality?

How long is your delivery time?

Can we visit your factory?

About the product price?

Can you arrange the shipment?

Can you provide sample?

RELATED PRODUCTS

GET A FREE QUOTE